Source: Michigan State University Extension, Kable Thurlow, Thomas Guthrie, Michigan State University Extension and Timothy Harrigan, MSU Dept. of Biosystems and Agricultural Engineering

Introduction

This bulletin covers the factors involved when selecting and installing an electric fence charger system to contain your livestock safely.

If properly constructed, a good fence should keep livestock contained and last 25 to 30 years without major repairs or total replacement. The old saying, “a good fence makes for good neighbors,” is true. Choosing high-quality materials when building your fence will ensure that it will be effective and last for many years. In some cases, electric fencing may be a significant part of a livestock operation’s fencing plan.

Electric fence technology has made notable advances in recent years. These technological advances have allowed livestock producers to increase their grazing operations’ management potential by attributing flexibility to the rotation of grazing resources. The major component of an electric fence is the charger or energizer; these two terms are used interchangeably throughout this document.

Low Impedance vs. High Impedance Chargers

Low impedance chargers are the most common fence chargers manufactured today. They are much safer than their predecessors, the high impedance chargers that used an AC high voltage output. Low impedance chargers can energize miles of single- or multiple-wire fences. They output a short-duration, high voltage DC current. The low impedance pulse is also extremely short compared to the long, slow pulse of the old high impedance chargers.

High impedance chargers are the typical fence chargers from years ago. They delivered a shock that was high voltage with low amperage. An amp is the amount of electricity that flows through the wire; this provides the jolt that deters predators and keeps livestock in the fenced-in area.

Old high impedance chargers, commonly known as “weed eaters” or “weed choppers,” may still be used but no longer marketed. These older chargers could potentially start a fire by burning through weeds. They deliver a shock long in duration with a high voltage. High impedance chargers are easily grounded out by vegetation, making them ineffective. Once this happens, little to no shock value is left for keeping livestock within the fence boundaries.

To overcome the problem of grounding out easily, manufacturers lengthened the pulse rate of these chargers. This made the pulse rate much longer than the pulse rate of the low impedance chargers. In some cases, the pulse rate could be 0.5 seconds, compared to low impedance pulses, which often are only 0.0003 seconds. Because of the longer pulse rate, these chargers sometimes caused fires.

Low Impedance Charger Types

The first step in determining what type of charger will work is to decide which type to use. The three main types of low impedance chargers for electric fencing include:

- Plug-in chargers

- Solar chargers

- Battery chargers

If there is access to a 110- or 220-volt service, plug-in chargers are probably the best choice. Plug-in chargers tend to be the most economical because there are no batteries to replace or recharge, and there are no solar panels to maintain. Solar and battery-powered chargers can provide sufficient output for livestock control. Technology advances with battery and solar-powered chargers have created reliable options. They provide the added flexibility of not needing an AC power source, which is convenient when pastures are in remote locations without electricity.

Fencing

The next step in selecting the size of the charger is to determine what type of fence will be energized. Several types of fencing materials are available:

- Woven wire fences are made up of horizontal wires connected by vertical wires called stays. The distance between the horizontal wires will vary from as little as two wires to as many as nine. The smaller spaces are used for smaller animals and the larger spaces for larger livestock. The overall height of fence wires will also vary depending on the class or species of livestock you need to contain.

- Barbed wire comprises two or more strands of smooth wire twisted together with usually four barbs spaced every 4 to 5 inches. Barbed wire should never be electrified. Livestock or a person could get entangled in the wire and unable to escape the electric shock.

- Temporary portable fencing consists of polywire, polytape, braided twine, and electric netting. This fencing is used in rotational grazing systems and is not suitable for permanent fencing. It is used inside of a good perimeter fence. The polywires usually have three to nine strands inside them that conduct the electricity. Electric net fencing is used in many poultry and small ruminant grazing systems. Netting is one of the better fence types for controlling predators.

Single-wire fences require less energy than multiple-wire fences. The multiple-wire systems will likely carry a higher vegetative load on the lower wires. Also, with multiple-wire fences, such as the standard five-wire high tensile fence, charging every other wire will reduce the total length of charged wire and the resulting load on the fence charger. You need to calculate the miles of fence using the total linear feet of all the hot wires, not just the length of the fence.

The type of fence can also affect the performance of the energizer and will help determine what output joules are required.

Grazing experts recommend a 12.5-gauge high tensile wire to achieve the most satisfactory results on a permanent exterior or semi-permanent interior fence. Many types of fences and fencing products are available for portable fences.

The type of animals grazed can also determine the fencing material or wire used. Some cow-calf producers prefer the woven wire style, nonelectric fence for safety instead of the high tensile single strand wires. These fences are found mainly along a busy roadway or near a residential area.

The area you plan to fence

When selecting the size of the charger, consider the type and total length of the fence. According to the University of Missouri Forage Systems Research Center, one joule of output per mile of energized fence wire is generally sufficient (Gerrish & Roberts, 1999). Therefore, before selecting an electric fence charger, acquiring a close estimate of the total distance of wire strands you plan to electrify will aid in selecting a charger with a mileage rating that meets those needs.

Example: You have a 15-acre pasture shaped like a rectangle that you need to fence with a 5-wire fence; three wires will be electrified. The total distance around the perimeter is 3,430 ft. X 3 wires = 10,290 ft. of energized wire divided by 5,280 ft./mile = 1.9 miles. Select a charger suitable for two miles of fence.

Once you choose the size of the charger, decide which type of charger to purchase. The installation location and availability of power will influence your choices. A plug-in charger will be the best choice when accessing 110- or 220-volt AC. These chargers eliminate the need to maintain batteries and solar panels for operation. Because they do not rely on a battery or sunlight for operation, plug-in chargers tend to be the more reliable and cheaper option. A higher joule output is often available for large acreage pastures with AC chargers.

Grounding

An electric fence system that is not adequately grounded will not perform up to its potential. It may not safely contain the livestock or keep predators out. When determining how to ground an electric fencing system properly, consider two main factors:

- The output capacity (joules) of the energizer

- The conductivity (siemens/meter) of the soil

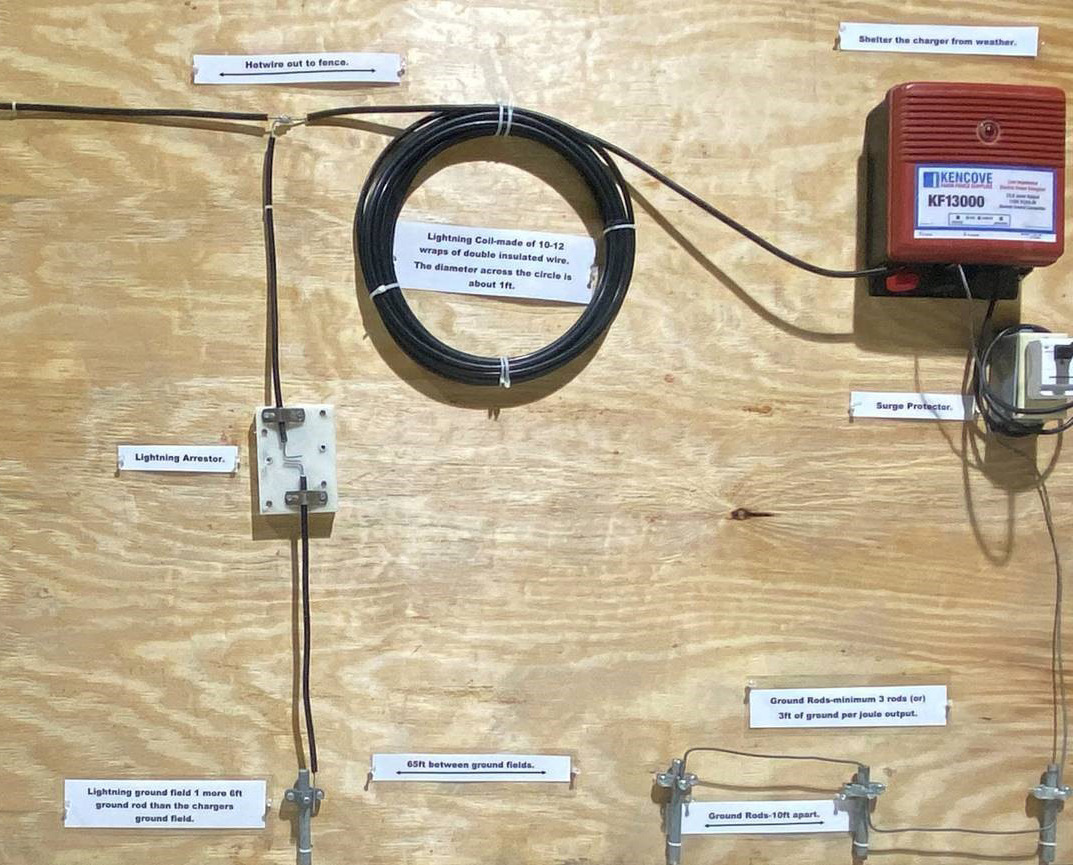

An energizer must be adequately grounded to energize to its potential. The greater the charger’s output, the more grounding rods are needed. A general rule is to install a minimum of 3 feet of grounding rod per joule of output capacity. Therefore, a 15-joule fence charger requires a minimum of 45 feet of grounding rod. Grounding rods must be installed at least 10 feet apart, and the wetter the ground, the better the grounding rod performance will be. Most grounding rods are made from galvanized steel or copper. The type of wire connecting the energizer to the grounding rod should be the same as the grounding rod to minimize corrosion from electrolysis resulting in poor performance.

You must be aware of any other grounding rods in the vicinity that may be used for a building’s electrical system. As a safety precaution, ensure the ground wire is not connected to any grounding rods used for other utilities such as those for electrical boxes. Locate the charger grounding rods at least 50 feet from other grounding rods and underground telephone or power cables.

Soils for grounding rods

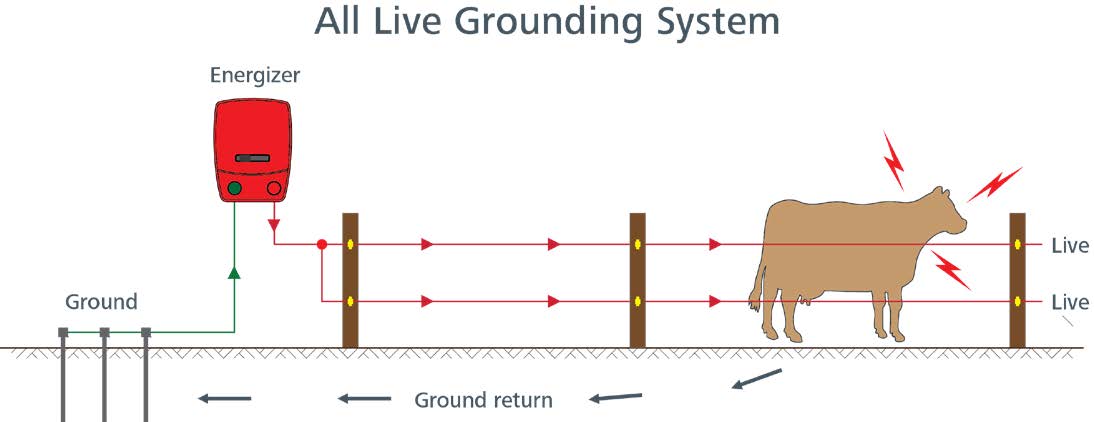

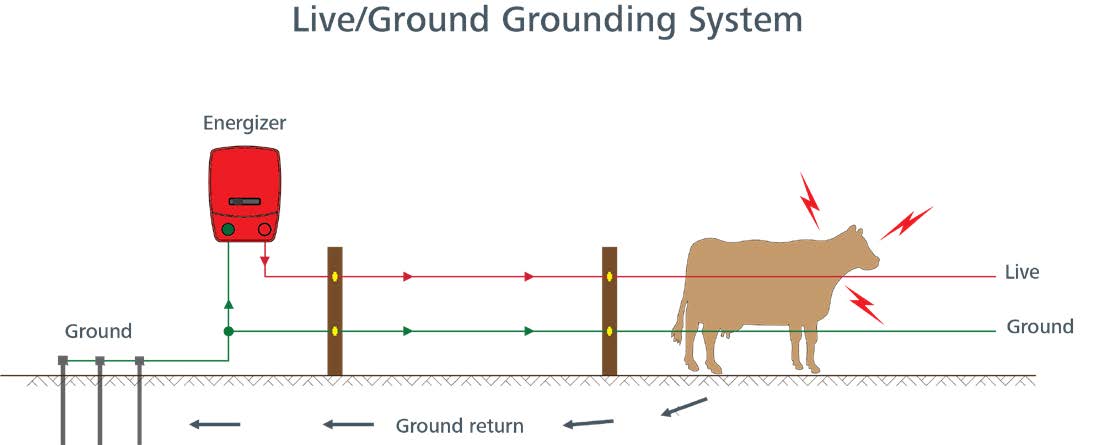

Sandy or rocky soils will not be as conductive as loamy soils, so a system installed on these soils may need to be an earth-return grounding system. An earth-return system is one in which alternate wires in the fence are ground wires. Charged wires on a system need to be connected back to the output connector on the energizer. (See Figure 1, which shows an all live grounding system.)

Earth-ground, noncharged wires need to link back to the ground terminal on the charger or to grounding rods in the fence lines. Experience at Michigan State University’s Lake City Research Center has shown that it’s better to place grounding rods below roof eaves on buildings in sandy soils to maintain the maximum moisture possible. However, keep a safe distance from other grounding rods used for the building’s electrical system. (See Figure 2, which shows an earth, or live/ground system.)

Earth-return systems typically control sheep or goats better. All other livestock can generally be managed without using the earth-ground system, provided the soil isn’t sandy, rocky, or extremely dry.

Voltage

A joule is the energy used to create voltage. In contrast, voltage refers to the current’s pressure moving throughout the fence line. Higher voltage increases the wire’s ability to shock an animal that touches an energized wire. Table 1 illustrates a representative voltage paired with the level of animal containment. Recommended voltage ranges for different animal species will vary. This can primarily depend on the hair coat thickness of animals and overall animal behavior. For example, horses can typically be deterred with 1,500 to 3,000 fence voltage, whereas 4,000 to 5,000 volts may be more appropriate for safely containing sheep and goats.

Table 1. Level of Animal Containment Based on Voltage

| Level of animal containment | Voltage range |

| Excellent | 5,000 v |

| Great | 4,000 v |

| Adequate | 3,000 v |

| Poor | 2,000 v |

| Very limited | 1,000 v |

Monitor voltage levels periodically using a fence tester. Do this in multiple locations to ensure adequate voltage. (See figures 3 and 4.)

Training Livestock to Electric Fences

Livestock must be trained to an electric fence before turning out in a pasture where a single- or multiple-wire fence may be their only barrier. Electric fences are a psychological barrier. If livestock are not trained before being put out to pasture, they may go through the fence when they receive their first shock. Introducing them to an electric fence involves exposing them to the electric wire where there is an actual physical barrier, such as a woven wire fence or corral and a charged electric wire.

Installation Tips & Safety Hazards

Low amperage and a short-duration, pulsating current make electric fencing relatively safe.

- When installing, be aware of any factors that could cause stray voltage. In many cases, this may be hard to pinpoint. However, a few places to be mindful of are around gates, waterers, and wellheads. If animals refuse or are reluctant to drink from a waterer, a stray voltage problem may exist. For more information on stray voltage, visit http://maec.msu.edu/pub.htm.

- Installing a lightning coil or lightning choke on the lead wire near the energizer will help guard against damage from a lightning strike.

-Lightning coil: six to eight wraps of a heavily insulated 12-gauge wire in an 8-inch to 12-inch diameter loop

-Lightning choke: a 10- to 12-loop coil of high tensile wire spaced approximately 2 inches apart on a mounting board made of wood or plastic (see Figure 5)

- Installing a lightning diverter where the lead-out wire connects to the fence will drain some energy from a lightning strike by sending it directly to the ground. It also serves as a route to ground for any energy diverted back to the fence by the lightning choke or lightning coil.

- In sporadic cases, an animal may die if it gets tangled in the fence for some time and is unable to release itself. Never electrify a barbed-wire fence; the possibility of animals or people getting entangled in the wire and injured is high.

- Appropriate signage makes it clear that the fence is electrified. Caution signs may be especially important if you have visitors to the farm, live in a community with many children, or have neighbors with pets.

In Summary

Low impedance chargers are safer and more efficient than their older high impedance counterparts. The three main types of low impedance chargers are plug-in, solar, and battery. To select the size of the charger, determine the type of fence you will need as well as the area you plan to fence. After you determine size, select the type of charger. Make sure your system is adequately grounded, keeping in mind the output capacity of the energizer as well as the conductivity of the soil. Train your livestock to an electric fence before turning them out to pasture. Read and follow the manufacturer’s recommendations during installation. A properly constructed electric fence made with high-quality materials will keep your livestock safe and contained.

Reference

Gerrish, J. R., & Roberts, C. A. (Eds.). (1999). Missouri grazing manual. MU Extension, University of Missouri–Columbia.